Chemical-Splash Resistant Coated Technical Textile Yarns Market: Grows at 8.2% CAGR and Forecast Outlook 2026 to 2036

Leading into 2026, regulatory shifts and application-specific requirements are redefining the global chemical-splash resistant coated textile yarns market.

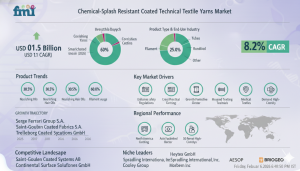

NEWARK, DE, UNITED STATES, February 6, 2026 /EINPresswire.com/ -- Future Market Insights (FMI), a leading provider of market intelligence and consulting services, today released its latest report on the Chemical-Splash Resistant Coated Technical Textile Yarns Market. The comprehensive study projects the global market to expand from USD 0.5 billion in 2026 to USD 1.1 billion by 2036, registering a compound annual growth rate (CAGR) of 8.2% over the forecast period. This growth outlook reflects rising regulatory scrutiny, tightening occupational safety standards, and increasing demand for high-performance protective textile materials across industrial and hazardous environments.

The report, titled “Chemical-Splash Resistant Coated Technical Textile Yarns Market Size and Share Forecast Outlook 2026 to 2036,” examines how advances in coating technologies, base yarn engineering, and regulatory compliance frameworks are reshaping the technical textiles landscape. By integrating PU, TPU, and advanced fluorine-free coating systems, manufacturers are developing yarns that deliver enhanced chemical barrier performance, thermal stability, and durability under repeated exposure. FMI’s analysis highlights the market’s transition away from general-purpose protective materials toward application-specific, regulation-driven yarn systems, supported by extensive data modeling, industry interviews, and regulatory trend assessments.

Market Drivers and Key Insights:

The expansion of the chemical-splash resistant coated technical textile yarns market is being driven by multiple structural factors. Increasing enforcement of workplace safety regulations across Europe and North America is compelling industries to upgrade protective apparel and technical materials used in chemical processing, pharmaceuticals, energy, and manufacturing. Regulatory developments under EU REACH and expanding chemical disclosure obligations in the United States are accelerating the phase-out of legacy PFAS-based coatings in favor of PFAS-free and low-VOC alternatives.

Data-backed insights from FMI indicate that compliance readiness and performance verification are becoming primary purchasing criteria. Buyers are prioritizing coated yarns that demonstrate consistent chemical resistance over repeated exposure cycles, laundering durability, and traceability across supply chains. Advances in material science including nanotechnology-enabled coatings, bio-based polymers, and hybrid coating architectures are enabling improved protection without compromising flexibility or wearer comfort.

However, the market faces notable constraints. High capital requirements for precision coating equipment, controlled curing environments, and skilled technical labor increase barriers to entry. Additionally, volatility in petrochemical-derived coating inputs and the complexity of navigating divergent regional chemical regulations present ongoing operational challenges for manufacturers.

Segmentation Analysis: Coating Systems, Base Yarns, and Applications

The chemical-splash resistant coated technical textile yarns market is segmented by coating system, base yarn type, and application, reflecting performance requirements across regulated industrial use cases.

In the coating system segment, PU and TPU coated yarns are projected to lead adoption, accounting for approximately 36% of total market share in 2026. These systems offer a balanced combination of chemical resistance, flexibility, and process stability, making them well suited for garments and technical assemblies exposed to repeated movement and handling.

By base yarn, polyester yarns dominate with an estimated 36% share, supported by their dimensional stability, predictable coating behavior, and global availability. Polyester’s consistency allows manufacturers to maintain tight quality control across multi-site production operations, a critical requirement for certified protective materials.

By application, chemical protective clothing represents the largest segment, accounting for roughly 45% of total demand. This dominance is driven by institutional purchasing cycles, mandatory PPE replacement schedules, and heightened liability considerations, which create stable and recurring demand for compliant coated yarn systems.

Request For Sample Report | Customize Report |Purchase Full Report - https://www.futuremarketinsights.com/reports/sample/rep-gb-31848

Regional Market Dynamics:

Geographically, the market displays differentiated growth patterns shaped by production capacity, regulatory enforcement, and industrial demand.

China holds a leading share in global production, supported by vertically integrated manufacturing ecosystems, automation, and rapid iteration capabilities for high-specification synthetic yarn systems. The country’s growth strategy is increasingly focused on technological control rather than capacity expansion.

In contrast, demand growth is accelerating in the United States and Europe, where stricter occupational safety enforcement and chemical disclosure requirements are reshaping procurement priorities. The United States is projected to grow at a 7.9% CAGR, driven by compliance-led upgrades in protective apparel.

Europe continues to benefit from strong regulatory frameworks that emphasize sustainability, traceability, and verified material performance. Emerging markets such as Brazil, growing at an estimated 8.0% CAGR, are gaining relevance through near-shoring strategies and specialization in sustainable and value-added technical textile production.

Competitive Landscape and Recent Developments:

The competitive landscape is characterized by a mix of global coated textile specialists and performance-driven technical material suppliers. Companies such as Saint-Gobain Coated Fabrics, Serge Ferrari Group, Trelleborg Coated Systems, Mehler Texnologies, Seaman Corporation, and Heytex GmbH are investing in coating innovation, regulatory alignment, and performance differentiation.

Strategic industry developments highlight this shift. Manufacturers are reallocating R&D toward PFAS-free chemistries, repeat-use reliability, and certification-ready product architectures. Corporate restructuring moves such as the separation of specialized protective materials businesses reflect a growing preference for focused, innovation-led operating models capable of responding quickly to regulatory and customer requirements.

Future Outlook and Industry Implications

Looking ahead, FMI forecasts sustained growth through 2036 as chemical-splash resistant coated technical textile yarns become integral to industrial safety and compliance strategies. Chemical resistance is increasingly viewed as a baseline requirement, while competitive differentiation is shifting toward durability, sustainability, and regulatory traceability.

As industries worldwide continue to upgrade protective systems and align with evolving safety standards, demand for lightweight, durable, and compliant coated yarn solutions is expected to remain strong. The market’s evolution underscores its strategic importance for manufacturers, regulators, and investors monitoring the future of high-performance technical textiles.

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Explore More Related Studies Published by FMI Research:

Strapping Tapes Market: https://www.futuremarketinsights.com/reports/strapping-tapes-market

Gusseted Bag Market: https://www.futuremarketinsights.com/reports/gusseted-bags-market

Non-Woven Fabric Market: https://www.futuremarketinsights.com/reports/non-woven-fabrics-market

Why FMI: Decisions that Change Outcomes- https://www.futuremarketinsights.com/why-fmi

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.